(www.MaritimeCyprus.com) What if you could have the option of Fleet Information Sharing in only few seconds without the necessity of going onboard? What if the Port State Control (PSC) inspection, P&I or the flag annual safety inspection could be materialised at any time or the review of a ship’s records or data could be completed before the vessel arrives into port?

With tens of thousands of cargo vessels sailing across the world’s oceans every day, the safety of cargo and human lives at sea depends on the periodic surveying and inspection of vessels to ensure they are safe to sail. The increased use of coordinated and harmonised ship safety inspection efforts from keel laying and throughout a ship’s lifetime has profoundly impacted the shipping industry and increased safety standards.

The history of ship inspections

The principal authorities that inspect vessels and certify their safety include PSC, Flag Registries, Classification Societies and P&I Clubs.

The history of PSC can be traced back to the first International Convention for the Safety of Life at Sea adopted in 1914, which already contained a provision necessitating the control of ships while in ports of Contracting Governments. In the decades that followed, the International Maritime Organization (IMO) continued to issue Assembly Resolutions that pertained to PSC making process well regulated.

Then, in 1978, the 'Hague Memorandum’ between a number of maritime authorities in Western Europe was developed. Although it was primarily concerned with the enforcement of shipboard living and working conditions, its establishment represented a huge step taken towards the strengthening of ship safety maintenance through inspections and was later followed by other Memorandums of Understanding, notably the Paris MOU, concerning the safeguarding of ship safety through the inspection process.

The future of ship inspections

Like all global industries, shipping is expanding and evolving.

Increased volume of trade, new regulations and the expansion of existing regulations, and differences between PSC regimes have posed new challenges to the modern system of PSC.

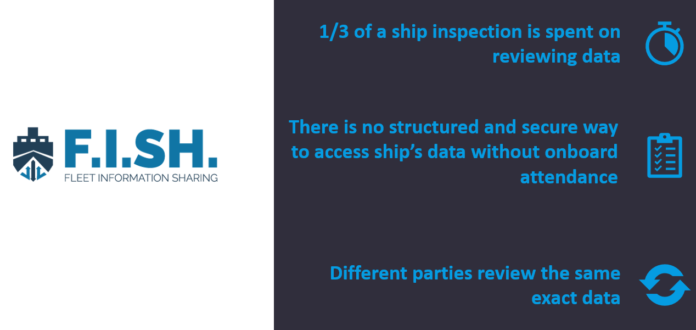

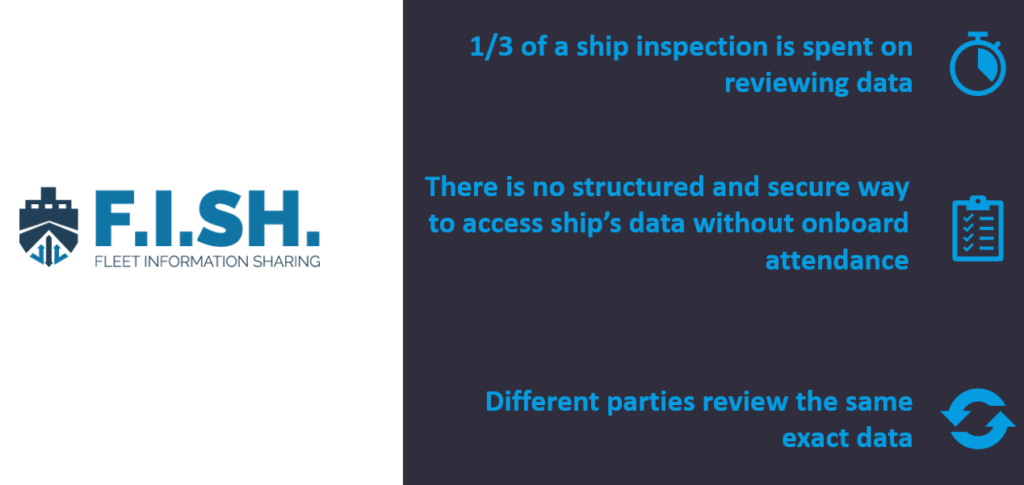

The completion of ship inspections involves significant time and expenditure. Most audits require the different auditing parties to repeatedly review the same records and documentation, such as logbooks, drills, records of ship operations, expiry dates and validity of certificates etc. Seafarers are also required to be in attendance during audits and inspections, which places great demand on their time.

In an industry that is undergoing digital transformation while facing great pressures to optimise operations and reduce costs, traditional methods for vessel inspections are being challenged by digital alternatives that seek to reduce the time spent during physical inspectors, or to remove the need completely. Certain classifications societies are investing heavily in the use of drones for their surveys and the transition to digital certificates in replacement of paper certificates is taking place at an increasing rate.

The COVID-19 pandemic has also challenged traditional vessel inspection methods due to restrictions around crew changes and inspector travel limitations to reduce the transmission of the virus between crew and those boarding vessels. On April 8, suspension of PSC inspections was announced by all 10 PSC regimes at a virtual summit hosted by the IMO. During the summit, the regimes agreed to a more targeted approach during COVID-19, to ensure the safety of their surveyors and inspectors. As such, PSC inspections were greatly reduced.

Flag states also found themselves in a tricky situation during the pandemic since their priority is to ensure vessels remain compliant and safe through annual inspections. They responded by providing extensions to inspections, in a similar way to PSC authorities.

During the pandemic there has been a greater reliance on remote surveys to protect crew and inspectors from spreading or contracting the virus. COVID-19 restrictions on inspections has definitely spurred an increased pivot towards digitalisation. Therefore, questions have arisen over whether this trend will continue, as well as over the effectiveness of remote surveys. Remote surveys and the use of digital documentation reduces inspector/surveyor time and also costs associated with their travel and accommodations. Forced into adopting a more remote way of working, could PSC authorities and flag states choose to adopt a more remote, digitalised and streamlined way of working going forward?

Time is money

Although the effectiveness of remote surveys and their limitations are being questioned, digital technologies that can help to reduce the time needed for vessel inspection procedures need to play a central role in the industry’s future.

"Time is money" – this is especially true for the shipping industry, because any day that a ship is not in transit, it is costing the shipowner money rather than making it.

What if the documents, records, expiry dates and other data such as work/rest hours required for a PSC inspection, or an flag annual safety inspection could be requested from the ship operator or manager for remote access by an inspector at any time or before the vessel arrives into port? Or what if previously requested ship records, data and documentation could be stored in a central database for easy access by inspectors at the next inspection, significantly reducing inspector time and cost and allowing for a greater number of inspections to be completed in the same time frame?

This is now a reality with the introduction of the ‘Fleet Information Sharing – F.I.SH.’ platform, developed by Prevention at Sea. The F.I.S.H platform was created through a project that commenced in March 2018, co-financed by the European Regional Development Fund (ERDF) as part of RESTART 2016-2020 of the Cypriot Research and Innovation Foundation (Prot. No. ENTREPRISES/0916/0134) and endorsed by the Cyprus Deputy Ministry of Shipping.

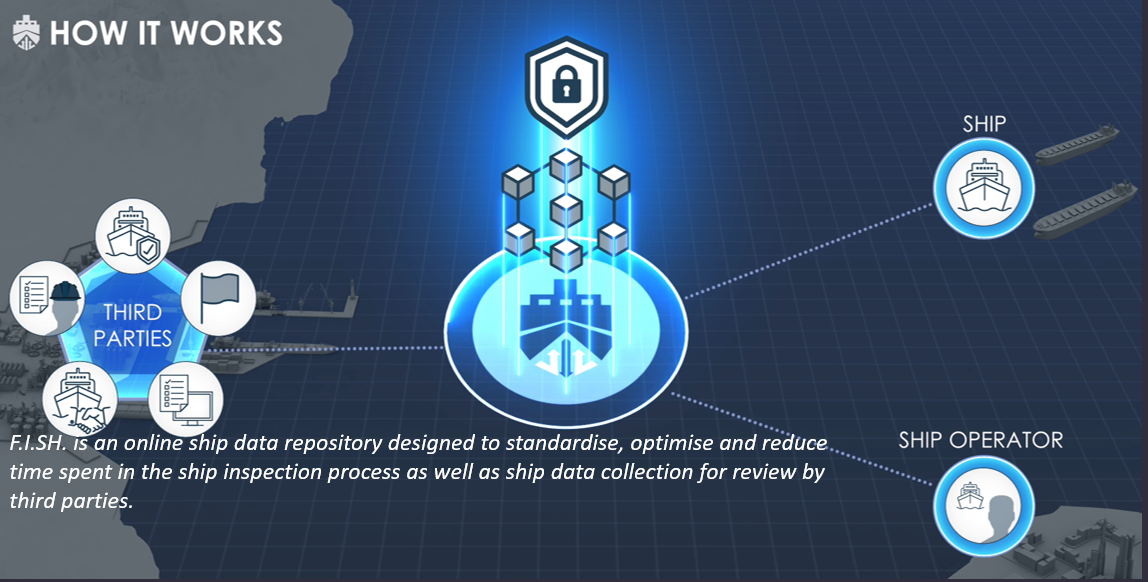

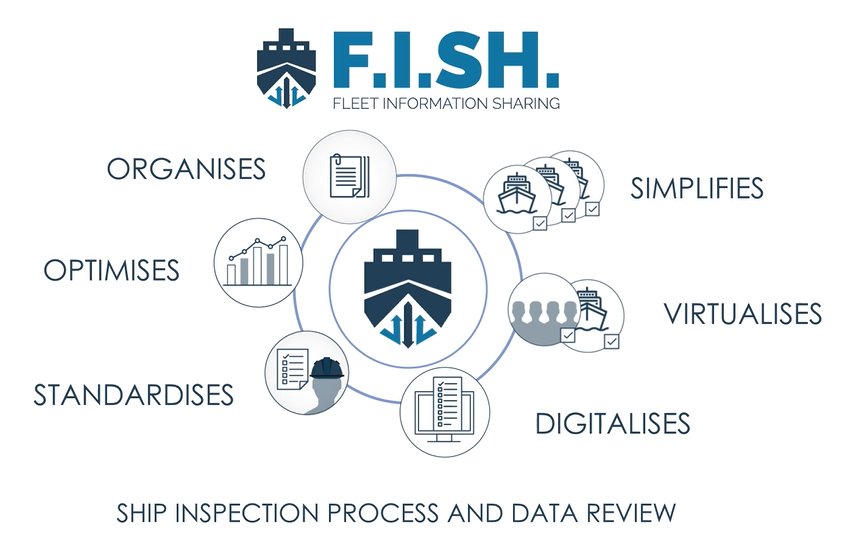

‘Fleet Information Sharing- F.I.SH.’ is an online ship data repository designed to standardise, optimise and reduce time spent in the ship inspection process as well as ship records/data collection for review by third parties.

The aim of the platform is to enable the digitalisation of the ship inspection process by helping 3rd parties to securely share data, supporting the significant reduction of administrative time and costs. As such, the F.I.SH.’ platform provides an innovative solution for ship data exchange between Third-Party stakeholders such as Flag States, P&l clubs, Charterers and Port State Control, the Ship and the Ship Operator.

Following the initial project completion and the commercialisation of the F.I.S.H platform, and as part of their continued support for the technology, the Cyprus Deputy Ministry of Shipping/Cyprus Ship Registry has expressed the willingness to use the F.I.S.H platform initially for their Flag Inspections and then, at a later stage, for PSC Inspections. Several other safety agencies and flag registries have also expressed an early interest in using the platform.

How does the F.I.S.H platform function?

Through the F.I.S.H platform, third parties are able to submit requests to the ship operator for online/remote ship data review or acquisition. Ship operators can review all of these requests and can grant or decline access to third parties, as well as assign access with functional (i.e. view only) or time restrictions. Once permission by the ship operator has been granted, the third party enquiring about the ship’s data/records will be able to access data and provide feedback to ship operators. This streamlines the ship inspection process and reduces the need for physical inspections.

The F.I.S.H platform allows ship operators and crew members to upload fleet data such as e-certificates, logbooks, ship records into a central and secure online system, as well as review and validate data that have been automatically acquired by other maritime electronic systems and platforms. As such, this platform is a key tool that supports the transition to remote inspection practices.

Ship documentation review can be completed remotely by the inspectors, allowing them to gain a clearer view of what to expect when they go onboard. This enables a detailed and systematic physical inspection of the ship with focus on more critical aspects such as the structural condition, maintenance, human element, etc. Obstacles such as remote port locations and weather conditions are no longer an issue, allowing the inspector to complete a remote inspection on ship’s data without necessary attendance; This also removes exposure of the inspector to risk.

Through F.I.SH., PSC inspectors can request access to ship data, review a ship’s data after acquiring access, provide feedback on the data reviewed, view inspection analytics and benchmarking, and view ship/fleet analytics and benchmarking.

For flag registries, annual flag state inspections are usually conducted by subcontractors are used worldwide. There can be a huge information disconnect here which results in the subcontractors asking the flag state for vessel records (which can be paper and electronic) which flag registries have already published, the subcontractor doesn’t know about. This adds complexity and time to the inspection process.

In response to disruptions caused by COVID-19, some flag registries have conducted remote annual safety inspections by exchanging controlled documents and sensitive records via emails. Therefore, it can be anticipated that more flag registries will move towards remote inspections and the need for a standardised and secured way to do so will rise.

F.I.SH. can be used as common data repository between flag registries and subcontractor inspectors conducting annual ship inspections. This would reduce the time spent by subcontractors locating documents for ships undergoing the annual flag registration inspection process and reduce time spent conducting physical inspections/reviews of documentation onboard. With F.I.SH., the flag registry can obtain a real-time picture of the ship’s records and status at any time.

The F.I.SH. platform:

- Provides a secure communication channel between Third parties, the Ship and the Ship Operator

- Manages data requests and facilitates the secure exchange of data between ship operators and third parties and subsequent storage of data on the cloud.

- Reduces administrative burden and allows time for efficient physical inspection or removes the need for physical inspections completely.

- Provides complete control to the ship operator, whether to grant access to the data requested.

- Enables integration with various existing electronic systems used by shipping companies that maintain ship/fleet data (i.e. PMS/ERP, ε-ORB, RHManagεr, N.ε.ΜΟ)

The platform enables:

- The online uploading of fleet data with offline use, allowing the app to be used under any conditions.

- The utilisation of ship data digitalisation (e-certificates, electronic logbooks etc).

- The management of certificates.

- Remote access on ship data at any time or before ship’s arrival at port.

- The evaluation of third party requests for remote access on ship data.

- The review of ship data online via a secured permission process.

- Ship and fleet validations.

- Big data analytics and benchmarking.

F.I.SH. offers users significant administrative time and cost reductions:

- Official ship’s records, data can be obtained within minutes.

- Reduces operating costs associated with human error.

F.I.SH. offers users complete data Security:

- All data uploaded to F.I.SH. is encrypted and secure.

- Secured permission process to review ship data online.

- Role based authorisation for data exchange.

- Secure cloud storage.

- Role based authorisation for data exchange.

- Blockchain technology for data security.

F.I.SH. offers unlimited data exchange between multiple stakeholders:

- Provision of a central platform for the request and upload/download of documents.

- Remote access on ship data at any time or before ship’s arrival at port.

F.I.SH. offers unlimited data storage:

- Store unlimited volumes of any kind of data (documents, images, videos) in the platform’s data reservoir.

Contact the experts: Prevention at Sea

email: info@preventionatsea.com

POOR EFFORT OF THE COMPANIES TRYING TO PROMOTE AND SELL SOMETHING THAT WILL NEVER WORK. SO-CALLED"REMOTE INSPECTIONS" WILL NEVER WORK. I AM FLAG INSPECTOR FOR 6 MAJOR FLAGS STATES FOR OVER 30 YEARS AS WELL AS AUDITOR AND SURVEYOR FOR ABOUT THE SAME PERIOD. MASTER OCENA GOING UNLIMITED .FORMER SHIP OWNER(300O GC IN WW TRADE-20 MONTHS). WILL GIVE YOU JUST ONE MOTS RECENT EXAMPLE WITHOUTH NAMING THE VESSEL OR PORT. SUBJECT GC VESSEL BUILT IN 2008 HAS UNDERGONE PSC USCG REMOTE INSPECTION 10 DAYS AGO. RESULT WAS :NO DEFICIENCIES/OBSERVATIONS. SAME VESSEL HAD UNDERGONE REMORE COMPANY INTERNAL AUDIT IN MARCH 2020. NOT A SINGLE OBSERVATION. SAME VESSEL WAS INSPECTED BY FLAG INSPECTOR RESULTING IN 13 DEFICIENCIES AND TWO OBSERVATIONS. ALL THOSE IN FAVOR OF REMORTE INSPECTIONS ARE THINKING ONLY OF TWO THINGS: HOW TO KEEP MONEY APROPRIATED FOR REMOTE INSPECTIONS IN THEIR ACCOUNTS WHILE STILL COMPLAYING WITH REQUIREMENTS FOR THIS INSPECTIONS . SECONDLY HOW TO GET MORE MONEY FOR TECHNLOGY AND APPS ETC THAT WILL BE INTRUDUCED TO OWNERS/OPERATORS ETC. I AM SURE THYE WILL SOON COME UP WITH ANOTHER COURSE TO SO CALL"TEACH AND FAMILIARIZE" CREW WITH THAT NEW TECHNILOGY. ALL THAT CLEARLY POINTS OUT TO TOTAL DISREGARD TO CREW ON BOARD AND THEIR NEEDS IN REAL TIME. COMMERCIAL SIDE FIRTS AT ALL THE COST. GAIN AS MANY SHIPS TO THE REGISTRY AS POSSIBLE FOR FINANCIAL BENEFIT. THAT IS WHAT IS IT ALL ABOUT. ALL IDEA ABOUT ISM SYSTEM AND NOT TO TALK ABOUT ISPS SYSTEM HAS BROUGHT AN ENORMUS BURDAIN TO THE MAJOR KEY PERSSONEL ON BOARD. MASTER,CH ENG,CH OFFICER WHERE THE AMONT OF THE PAPER WORK THAT THEY HAVE TO DEAL ON DAILY BASIS DOES NOT ALLOWE THEM THE TIME TO TO THEIR REAL JOBS. DOES ANYBODY CARES? NOT EXACTLY. IT BECAME MORE IMPORTANT WHAT IS WRITTEN ON THE PAPER THAN A REAL LIFE CONDITION. IF ANYTHING GOES WRONG GOD HELP THE MASTER AND CH ENG IF THEIR PAERWORK IS INCOMPLETE OR MISSING. ITS THE LIABILITY THAT EVERYBODY IS AFTER IN CASE OF MAJOR PROBLEMS. NEADLESS TO SAY, FLAG STATES/OWNERS/OPERATORS/CLASS/PSC/PILOTS EVEN FLAG INSPECTORS ARE FINANCILAY MUCH BETTER SUPPORTED THAT CREW ON BOARD AND IN CASE OF NEED LEGAL DEFENSE IS THE THEIR FINGER TIP. WHAT THE CREW HAS. THEIR LICENSE AND SOME SAVINGS OVER THE YEAR. SO THEY WILL FALL FIRST. SHAME TO ALL WHO HAVE CONTRIBUTED TO THIS "MONSTER" OF PAPERWORLD ON THE SHIPS. ISPS..ANOTHER BILLION $ MONEY MAKER.